What is RVS?

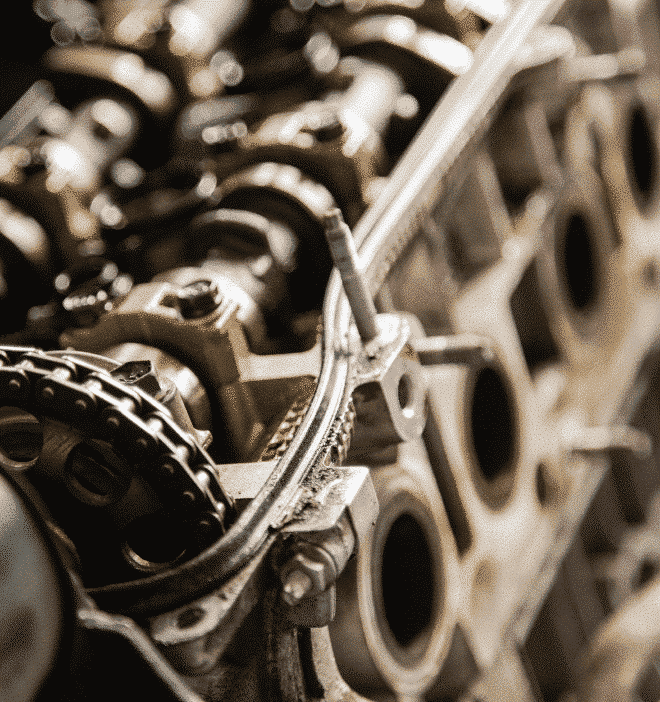

Finnish patented and tested product family for protection and restoration of internal combustion engines, transmissions, and other mechanical equipment, which means minimising energy losses and improving usability.

Read more

The RVS Technology® products have been designed to improve the performance and durability of engines and other mechanical systems. They are not oils or oil additives, but an innovative technology based on a ceramic treatment.

The efficiency of the RVS Technology® is based on a ceramic treatment that reduces energy consumption and emissions. In a triboceramic treatment procedure, certain components of the RVS compound react with the metal surfaces of the mechanism being treated and produce a thin protective layer.

The layer reduces friction and wear, which prolongs the operational life of the device and improves its performance. The layer is not easy to detect with the naked eye as it is rather glass-like. The smooth surface material can, however, be detected with a multimeter; ceramics do not conduct electricity.

When you choose an RVS treatment for your device, you get plenty of benefits: lower energy consumption, higher power, and a longer operational life.

How it worksMake your engine work longer and produce more power while you save on fuel costs.

Has the fuel consumption of your car increased? Does the engine make more noise, or has the transmission stopped working as smoothly as it used to? Would you like to minimise shut-downs caused by repair work? Or do you just want to increase power and torque? Do you have a new engine that you want to keep in good condition for a long time?

An RVS treatment does not repair mechanical defects, but it can be used to get rid of wear in its initial state and to significantly prolong the operational life of mechanical components and vehicles.

A new problem that has occurred only recently is the internal corrosion of the combustion engines of plug-in hybrid vehicles. It is caused by the fact that the engines run at optimal temperatures very rarely if they are driven over short distances, and the moisture formed inside the engine cannot evaporate.

The moisture causes corrosion, especially on camshafts that are not typically in oil baths. As ceramics do not corrode, an RVS treatment prevents a corrosion problem very effectively.

We recommend you try using the RVS products. You will be positively surprised!

See test results

By choosing the RVS products:

- you increase the performance and reliability of your devices

- you reduce energy consumption, as a result of which the operating costs and emissions are reduced as well

- you extend the service intervals and operational life

An RVS treatment always pays back the costs

An RVS treatment gives a long-lasting effect, and you do not have to renew the treatment after every oil change. For instance, in normal road use, the effect lasts for about 100,000 km (65,000 miles).

Find the optimal products for your vehicle

RVS Technology® – designed and produced in Finland

The innovative RVS Technology® products are made with over 20 years of experience. The majority of the production cycle takes place in Finland.

Read more

Using RVS Technology® products is easy and safe

You can easily treat your device yourself. For a successful result, it is enough that you follow the detailed but simple multilingual instruction manual included in the consumer package. With our products, updating your engine, transmission, and power steering to a new level is straightforward and effortless!

For professional use, we give instructions for the mechanisms you intend to treat, or alternatively, we can offer you the entire process as a comprehensive service.

Take a closer look at our products

RVS is a sustainable choice with a durable effect

The RVS treatment is an environmentally sustainable choice. When the engine undergoes RVS treatment, its internal components are effectively cleaned at the same time. Not only do emissions decrease by 5–25% as a result of RVS treatment, but the fuel also burns in the engine more cleanly, optimising its performance and reducing the formation of harmful residues. Due to the cleaner combustion, overall emissions decrease more than what could be expected based solely on a reduction in fuel consumption.

Frequently asked questions

-

The abbreviation RVS stands for Restores Vital Surfaces.

-

Our products are classified based on the oil capacity of the mechanism to be treated. You can find the right product by checking the oil capacity in your user manual or by writing the license plate number of your vehicle in a search field on our website (for selected regions only).

If the oil capacity of a petrol engine is 4 litres, you need a G4 product. If it contains 5 litres of oil, you need the subsequent product, i.e., G6, that is made for 4–6 litres. If the engine has 10 litres of oil, you can combine the packages, and you need one G4 and one G6 package. For diesel engines, you use D-series products, and for transmissions, you use T-series products with the same principle. Gas and ethanol-driven engines are like petrol engines from the RVS point of view, and they are treated with G-series products. If you do not know the oil capacities of your vehicle, you can normally find them in its user manual. You can always contact us in order to find the right product!

-

In the treatment process, you normally use the lubricant or fuel that carries the RVS substance to the locations where it reacts. To put it simply, you can say that the RVS substance is put into the lubricant or fuel, and you use the mechanism for a certain minimal time. You can find detailed instructions for different RVS Technology® products on the product pages of each of them. For industrial purposes, we give instructions for a concrete mechanism or, if needed, we can organise a comprehensive service.

-

The benefits of an RVS treatment are long-lasting. You do not have to renew a treatment after an oil change, as oil changes do not affect an RVS Technology® treatment. The RVS product forms a nanoceramic layer that integrates the metal surfaces prone to friction. An RVS treatment does not affect the properties of the oil it is poured into. That is why it lasts for approximately 100,000 kilometres (65,000 miles) in cars that are used in normal road conditions.

Contact us

If you wish to ask us about our products, you can contact us by using the form below.

"*" indicates required fields